Milestones

The Birth

A merger between ANSCOR and PDIC formed Phelps Dodge Philippines (PDP).

Local Manufacture

The country’s dependence on imported rods ended when PDP acquired its own mill and started manufacturing 8mm rods from wire bars.

PLDT Partnership

PDP began a long-term partnership with the Philippine Long Distance and Telephone Company (PLDT).

NAPOCOR Cooperation

PDP was the first manufacturer to locally produce 795 MCM Condor Aluminum Wires used by the National Power Corporation (NAPOCOR).

Aluminum Magnet Wires

PDP started manufacturing aluminum magnet wires and acquired key production equipment, bringing it to the forefront of the industry: the Maillefer PM-11 Tandem Extruder Line and the Maillefer PM-12 Extrusion Line, the only ones of each kind in the country.

Copper Rods From Cathodes

Through the operations of its Outokumpu Continuous Cast Rod plant, PDP acquired the capability to make copper rods from cathodes.

Asia Export

PDP started exporting copper rods to Hong Kong, Singapore, and Taiwan.

UL Approval

Underwriter’s Laboratories (UL) approved PDP building wires, making it the only wire and cable company with UL approval in the country.

Global Export

PDP started exporting its building wires globally.

Phone Cables for PLDT

The first Foam-Skin Filled (FSF) Telephone Cables were produced by PDP for PLDT.

35 KV Power Cables

PDP produced the first and only dry-cured, high-quality power cables up to 35 KV.

ISO Certification

PDP became the first local electric wire and cable company to have earned ISO 9001 Certification, raising the bar for the local industry.

Tarlac Plant

PDP established Phelps Dodge Philippines Energy Products Corporation (PDE) to consolidate all the manufacturing operations of the various entities under PDP and provide focus to its growing manufacturing activities. The operation of the plant was relocated from Mandaluyong City to Tarlac.

Anti Theft Cables

PDP introduced to the local power utilities the bipolar anti-theft cables, which helped eliminate power pilferage, thus reducing system losses. This product had been developed by PDP’s affiliates in South America and was being used by South American power utilities.

Lead FREE Cables

PDP reformulated all its THHN/THWN building wires to be lead-free wires.

PDP introduced lead-free CT-rated building wires

PDP introduced lead-free cable tray-rated building wires, enabling up to 30% savings on wire installations.

Halogen FREE Cables

Low-smoke halogen-free cables were produced at the PDP plant and introduced to the industrial and commercial sector.

General Cable As Majority Shareholder of PDP

General Cable became the majority owner of Phelps Dodge Philippines after Andres Soriano Corp. (ANSCOR) had sold some of its shares to General Cable.

Alumilite

PDP launched Alumilite®, an aluminum alloy building wire with a slippery additive (Flexiglide™), to meet the needs of its clients.

THHN/THWN-2 Cu Building Wire

First in the country to introduce THHN/THWN-2 building wire that is moisture and heat resistant, flame retardant, and suitable for 90oC wet and dry applications.

Versaduct®

PDP introduced its own busway system called Versaduct® to the general market for various applications in electrical distribution.

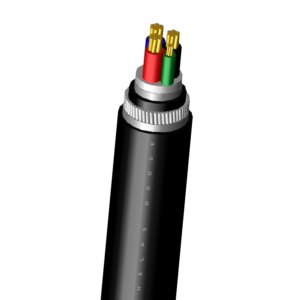

Metal Clad (MC) Cables

PDP was the first company to have produced and offered metal-clad (MC) cables with either copper or aluminum 8000 series conductor in the Philippines.

100% ANSCOR

PDP was 100% locally owned by Andres Soriano Corp. (ANSCOR) but still maintained a technical and exclusive distribution agreement with General Cable.

Locally Manufactured Branch Cable

PDP started locally manufacturing branch cables. This was a pre-fabricated cable solution that provided a cost-effective alternative to conventional cables or bus ducts.

Expanded CCV

PDP expanded its Continuous Catenary Vulcanization (CCV) Line to produce 3-layer Tree Wire to meet the growing demands of the market.

EV Charger

PDP introduced EV Chargers to the market that came in various types. They were safe, efficient, and convenient with their advanced features. This innovation promoted sustainable transportation.

PD Electrical Tape

PDP produced its first-ever electrical tape (PD Tape) in 16 meters and had six colors (red, black, blue, green, yellow, white).

Tarlac Plant Solar Power Project

Our Tarlac manufacturing plant is now powered by solar energy, making significant strides toward sustainability and energy efficiency. This step reinforces our commitment to reducing our environmental impact.

This Is Happy Title

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Iusto, optio, dolorum provident rerum aut hic quasi placeat iure tempora laudantium ipsa ad debitis unde? Iste voluptatibus minus veritatis qui ut

This Is Happy Title

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Iusto, optio, dolorum provident rerum aut hic quasi placeat iure tempora laudantium ipsa ad debitis unde? Iste voluptatibus minus veritatis qui ut